Sustainability is an aspect that must be incorporated into all industries, including manufacturing.Mechanical processing company Periholz (Elgo Ibar, Guipuzcoa) and Ametz (Llodio, Álava) knew this and, therefore, they committed to research project belmek. This is an initiative aimed at adapting traditional manufacturing processes to the new European Green Pact or Green Deal, so Transform it into a more sustainable, healthy and competitive process.

Incorporate assistance programs to support corporate R&D Haztec, and cooperation with technology centers Tenalia, Basque Union member BRTA,as well as UPV/EHU, This project aims to achieve Five technical goals key application concepts green manufacturing.The first of which is Complete elimination of hazardous cutting oils and coolants And give priority to vegetable oils. To this end, it is recommended to implement integrated CO2 and MQL (minimum quantity lubrication) solutions at the industrial level.

Improve efficiency machining process From an energy consumption perspective is the second goal. To do this, we will seek to optimize the relationship between material removal and energy consumption.Additionally, the third objective will seek to Maximize life cycle cutting tools, thus reaching a quarter, Reduce expense Related to processing technology.

Finally, BERMEK pursues Minimize waste during processing Due to reduced coolant usage. “Coolant is commonly used during the machining of metal parts to remove chips from the metal parts,” project management explained. However, “it generates waste, such as coolant-soaked shavings, filters and sludge, which needs to be recycled or eliminated.” The technology developed in the project does not generate any waste or components that must be recycled or eliminated. “That is to say, All excess materials can be directly reused as raw materials, facilitating their reuse.”, they clarified.

This will not only affect sustainability improvements, will improve the quality of life of workers mechanical processing technology.And, according to project managers, “the use of coolants can create problems such as skin irritation, acne, loss of lung function, pneumonia, and even skin or lung cancer.” So this project is a step Taking into account health and environmental protection Have stronger global competitiveness.

Two companies with a long history

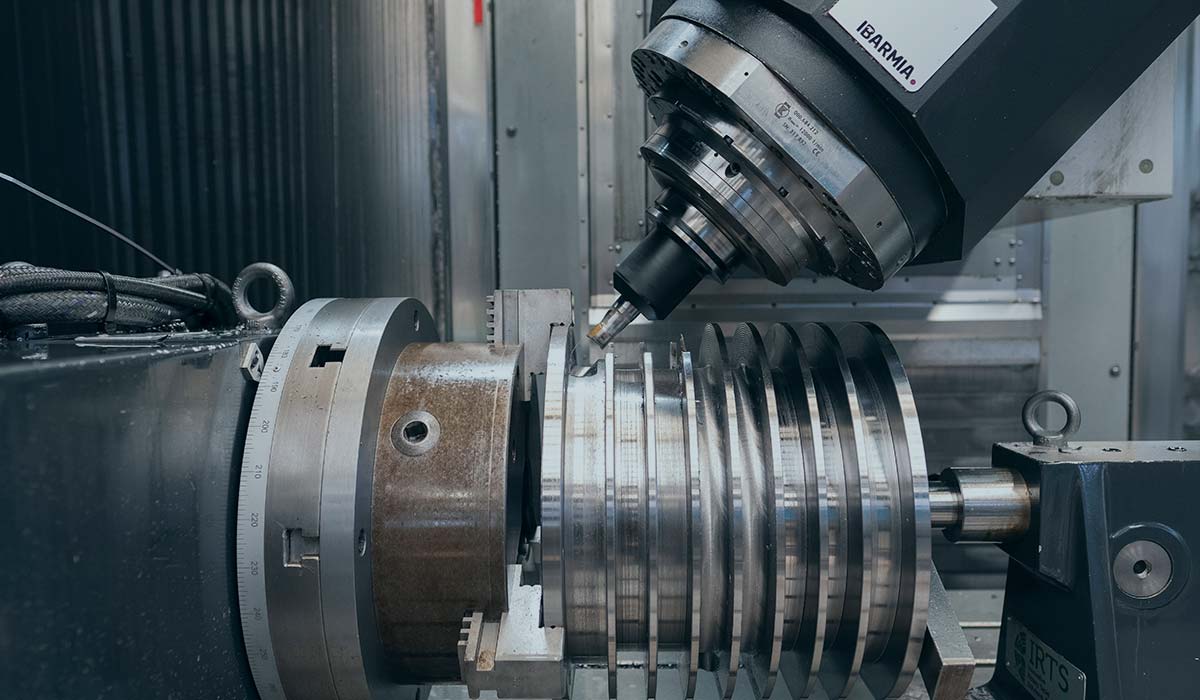

Periholz Since 1996, the company, headquartered in Elgoibar, Guipuzcoa, has been processing ferrous, non-ferrous, plastic and composite parts.It is part of the BIM Group and sold together with Customers from 12 different countriesMainly in Europe, involving various industries such as hydraulics, railways, chemicals and steel.

AmetzFor its part, its journey began in 1979 in Llodio (Alava). Since then it has been dedicated to the processing of all types of materials for various types and difficult parts in industries such as oil and gas, foundry or energy. others.With over 40 years of experience, it positions itself as Provide processing reference for companies in the region and resolved Work at national and international levels.

The SPRI Group promotes R&D among Basque companies through tools, assets, assistance, working groups and alliances to promote research and generate new technologies.consult R&D Assistance Program For example Elkartek, Emaitek or Hazitek.